Founded by George Sneckner and William (Bill) Elliott, Sneckner Elliot Manufacturing (SEM) opened its doors in Belmont, California to deliver high quality residential paints.

SEM is purchased by Don and Marilyn Scranton. The Scrantons sold a portion of the company back to their employees, believing that if the company took care of its people, the people would take care of the company. This act transformed the culture of SEM.

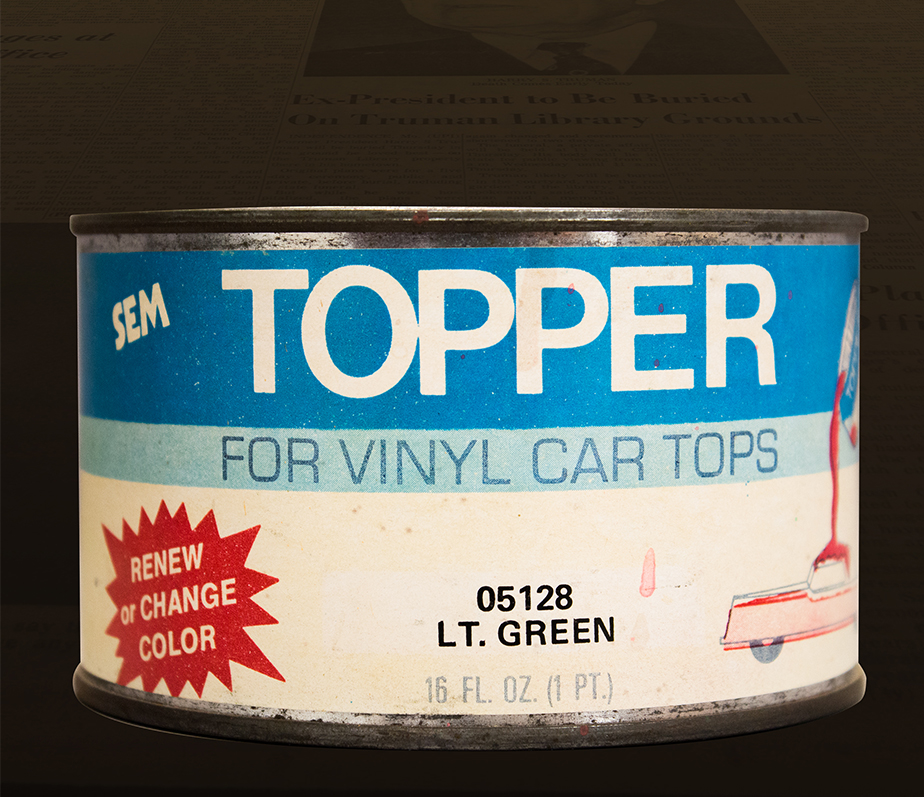

SEM enters automotive aftermarket with Topper, the first flexible coating for restoring or changing the color of vinyl car tops.

SEM revolutionizes interior refinishing with Color Coat, the first flexible coating, mixing system on the market. This allowed jobbers to custom match colors to restore or change the color of automotive vinyl, plastic, carpet, and velour.

SEM enters into the Custom Finish market with acrylic lacquer line of 12 super translucent candy colors. Shortly after, SEM expands with pearls, fluorescents, flakes, base colors, clears, and matte finishes.

SEM develops Bumper Coater, the first product to restore the OEM finish on new plastic bumpers and cladding. Originally available in bulk, it gained popularity so quickly, that aerosol versions were introduced shortly after.

SEM creates the first flexible clear additive, Super SEM Flex, allowing technicians to add flexibility to urethanes, enamels, and lacquers for bumpers, vinyl convertible tops, and flexible plastics.

SEM grows at exponential rates, causing the company to relocate from Belmont, CA to Charlotte, NC to expand production. All but one family relocated with the move and several of those families are still employees today.

SEM aerosol products continue to gain popularity by saving technicians time and reducing waste in collision centers. SEM expands operations by opening an aerosol plant in Rockingham, NC, providing more American jobs.

SEM responds to the need for waterborne flexible coatings with Sure-Coat, the first waterborne mixing system for refinishing leather, vinyl, and plastic.

Dualie is born. This iconic SEM mascot represents the tenacity and strength associated with bulldogs. He is named after our OEM Recommended, Forever Warrantied two-component cartridge brand, Dual-Mix™.

SEM produces the first sprayable Professional Truckbed Liner Kit. Originally available in black, a tintable kit was produced shortly after because of high demand and popularity.

SEM’s waterborne flexible coating system, Aerospace Sure-Coat, is approved Boeing to refinish aerospace interiors. Shortly after, Sure-Coat gains approval from the FAA for all commercial airlines.

SEM Products moves to a new location in Rock Hill, SC bringing the whole team under one roof. From new product design to production and shipping, the full product life cycle happens here.

SEM produces Ez Coat, the first coating to match color and gloss of OEM e-coat. Originally released in 6 OEM-matched colors, the line has expanded to 9 options to replicate the latest colors.

SEM is the first and only manufacturer to offer all 4 OEM colors in one-component seam sealers: Black, Gray, Beige, and White. Two years later, all colors are available in two-component options. All seam sealers are direct to metal and paintable immediately, saving time and materials in every application.

SEM obtains 53 OEM recommendations covering 221 products. Recommended product categories include panel bonding adhesives, structural impact repair adhesive, foams, plastic repair materials, seam sealers, adhesives, undercoatings, stone guard coatings, and specialty coatings.

All Dual-Mix™ products are OEM Recommended and Forever Warrantied, offering the strongest assurance of performance in the industry.

Fiat Chrysler Automobiles awards SEM 14 new OEM recommendations, bringing SEM’s total count to 67 OEM recommendations, covering 221 products. New FCA recommendations span product categories including Adhesives, Foams and Sound Dampening, Seam Sealers and Plastic Repair.

Product Innovation

SEM builds best in class products designed to reduce repair time, steps, and waste in every application. Since 1948 we have challenged ourselves to create original products that solve our users’ problems.

We also pioneer new repair or refinish procedures altogether because we refuse to rest on our laurels. Our SEM employees relentlessly challenge norms and exceed expectations to provide innovative products that reduce cycle times and increase throughput.